Pressure is a matter of attitude

If you bring a properly manufactured insulation glass to a higher elevation the enclosed gas expands due to the lower atmospheric pressure. An overpressure is evolved In the cavity that bends the glasses and puts pressure on the edge bond. This might lead to glass breakage, but it surely reduces the lifetime of the insulation glass - depending on the construction and the altitude difference. Another negative side effect is the distorted reflection.

Pressure balance - or pressure equalisation if you will - of insulated glass is becoming ever more frequently necessary due to the constantly increasing proportion of triple glazing, larger formats, asymmetric structures and long transport paths. Depending on the structure, pressure balance is recommended starting with a difference in altitude of 400 - 500 meters between the production site and the installation site.

This is no problem! With the HELANTEC ISO-Altimeter PROFESSIONAL you can execute this task in no time at all. Using the ISO-Altimeter PROFESSIONAL the IG unit is prepared in production in such a manner that it is flat at the higher (or lower) altitude of the installation site. Additional after-treatment is not required!

The HELANTEC valve is a small but important detail. Only with this valve can it be ensured that the executed pressure balance remains intact and that your assured characteristic of the IG unit does not change.

Alternative approaches

Capillary tube

In former times those were the only solution - despite its cumbersome installation. A small metal tube is put into the spacer bar while the far end connects to the air. Depending on the over-pressure or under-pressure in the DGU a certain amout of gas or (moist) air can continuously leave or enter the space between the glasses. Sooner or later, there will be no more gas but pure air. So the insulation value is less than at the beginning. Plus, the desiccant has to aborb a lot more moisture. A shorter lifetime is the result.

You can close the capillary tube at the installation place, but only if you get access to it. This would be possible with structural glazing but proofs difficult with completed windows.

Pressure release valve, breathing socket

At a certain value of pressure the valve opens and releases gas or introduces air. This pressure can be rather high. So again, the insulation value and the lifetime of the DGU are reduced.

ISO-Altimeter PROFESSIONAL

With the ISO-Altimeter PROFESSIONAL the IG unit is prepared in production in such a manner that it is flat at the higher altitude or lower altitude of the installation site. Additional after-treatment is not required!

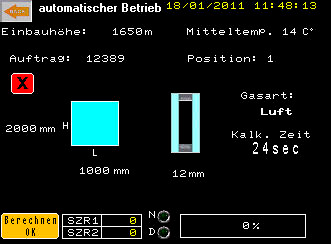

The ISO-Altimeter PROFESSIONAL is the further development of our proven predecessor model. Intuitive operation via touch screen, clear user guidance and versatile functions are only a few of the features that characterise our pressure balance system.

To achieve short cycle times, there has been a conversion to completely new technology. This enables us to execute the pressure balance with the highest accuracy and within the shortest time possible. To avoid operating errors, all data required for the pressure balance is loaded automatically from a list. The most efficient procedure is simply scanning a barcode on the IG unit.

The ISO-Altimeter PROFESSIONAL is a complete system for which no additional PC is required. All you need is a power connection and you can balance the pressure of IG units for higher-altitude installation sites. In this regard, vacuum pressure in the IG unit is generated in production. Through this measure the IG unit will be flat at the higher-altitude installation site.

Other special characteristics

- Pressure is balanced on the basis of the average annual climatic values at the installation site.

- The actual production conditions, (temperature and air pressure) are considered.

- Suitable for double glazed and triple glazed insulated glass (symmetric and asymmetric).

- Suitable for special formats (triangle, parallelogram, circle, etc.).

- Suitable for all standard gases.

- Processing of data exported from every order processing software program.

- Automatic documentation of each pressure-compensated IG unit.

- Connection to a central database – easy management of evidence if there are complaints.

- Data transmission, remote query and remote maintenance via network connection.

Naturally we also take into consideration the average yearly climatic conditions at the installation site, which in some cases is of major significance for the pressure balance.

If your production is located at an altitude that is higher than the subsequent installation site, naturally with our pressure balancing system you can also pressure balance the IG units. For this, you require only a gas bottle (compressed air, argon or krypton), to generate excess pressure in the IG unit, so that your IG unit is flat at the lower-altitude installation site.

The HELANTEC valve is a small but important detail. Only with this valve can it be ensured that the executed pressure balance remains intact and that your assured characteristic of the IG unit does not change.

ISO-Altimeter BASIC

With the ISO-Altimeter BASIC the IG unit is prepared in production in such a manner that it is flat at the higher altitude or lower altitude of the installation site. Additional after-treatment is not required!

The ISO-Altimeter BASIC is the further development of our proven predecessor model. Intuitive operation via touch screen, clear user guidance and versatile functions are only a few of the features that characterise our pressure balance system.

Other special characteristics

- Pressure is balanced on the basis of the average annual climatic values at the installation site.

- The actual production conditions, (temperature) are considered.

- Suitable for double glazed and triple glazed insulated glass (using a T-connector).

- Suitable for special formats (triangle, parallelogram, circle, etc.).

- Suitable for all standard gases.

To achieve short cycle times, there has been a conversion to completely new technology. This enables us to execute the pressure balance with the highest accuracy and within the shortest time possible.

The ISO-Altimeter BASIC is a complete system for which no additional PC is required. All you need is a power connection and you can balance the pressure of IG units for higher-altitude installation sites. In this regard, vacuum pressure in the IG unit is generated in production. Through this measure the IG unit will be flat at the higher-altitude installation site.

If your production is located at an altitude that is higher than the subsequent installation site, naturally with our pressure balancing system you can also pressure balance the IG units. For this, you require only a gas bottle (compressed air, argon or krypton), to generate excess pressure in the IG unit, so that your IG unit is flat at the lower-altitude installation site.

Naturally we also take into consideration the average yearly climatic conditions at the installation site, which in some cases is of major significance for the pressure balance.

The HELANTEC valve is a small but important detail. Only with this valve can it be ensured that the executed pressure balance remains intact and that your assured characteristic of the IG unit does not change.

JalouSET

Smooth-running venetian blinds at any time

Each and every IG unit is prepared in the production in such a manner that there is a wide enough gap between the panes so that the blinds don’t touch. Additional after-treatment is not required!

The HELANTEC valve is a small but important detail. Only with this valve can it be ensured that the executed pressure balance remains intact and that your assured characteristic of the IG unit does not change.

Highlights

- Highest precision by high resolution pressure sensors

- Safe operation because of intuitive construction

HELANTEC-Ventil

The HELANTEC valve is the key to success for correct pressure balancing, and for maintaining your assured characteristics for the IG unit.

With our ISO-Altimeter PROFESSIONAL pressure balance system the IG unit is prepared in production in such a manner that it is flat at the higher (or lower) altitude of the installation site. In this regard the HELANTEC valve is used for safe sealing during and after the pressure balancing.

Naturally the leak-tightness and material compatibility are tested and certified. Consequently the HELANTEC valve is used instead of the well-known sleeve plug system for manual gas filling technology.

More than 3.2 million HELANTEC valves are already in use around the world. Rely on this proven and progressive technology.

Comparison with other approaches

| Helantec Ventil | Pressure release valve | Drilled hole | Breathing socket | Capillary tube | Two way valve | |

| Gas tightness | yes | no | possible | no | possible | no |

| After treatment | none | none | necessary | possible | necessary | none |

| Respects annual average | yes | no | no | no | no | no |

| Respects local conditions | yes | no | yes | no | yes | no |

| Installation | simple | complex | simple | complex | complex | complex |