Perfectly tested quality

The origin of HELANTEC is gas analysis. For more than 30 years, HELANTEC has been delivering gas analysers for quality control of IG units. Most of these gas meters, “made in Germany”, that we developed specially for the use in the insulated glass industry are still in operation today.

The HELOX 4 and ISO-GAS-CONTROL analysers are in operation around the world. They are used by accredited test companies, in labs for insulated glass companies, as well as in production.

For us, standing still means moving backwards. Consequently we constantly optimise our analysers and develop new types. Many of these innovations are based on the suggestions of our customers; and we also consistently develop new ideas for further development on our own. This interaction of customer requirement and technical feasibility is a reflection of our success.

One result of this interaction is our newest analyser, the GAS INSPECTOR. It represents a new generation of analysers for quality control. It was developed for all companies that view quality monitoring as a management task.

The measured gas concentration can be saved combined with the barcode of the IG unit. In this process the data is integrated into company’s internal quality management system, via the integrated network interface.

We have developed the hand-held gas meter type, the GAS TESTER as a new and lower-priced entry-level model. Naturally, the proven analysis technology with reliable concentration measurement is integrated in this product as well.

We would be pleased to advise you in the selection of a suitable analyser. Surely we will find a device that is suitable for your requirements.

HELOX 4

The HELOX 4 has been a proven test instrument for quality control of IG units for more than 30 years. The analyser is preferred by test institutes and the central labs of the insulated glass manufacturers.

A paramagnetic measuring cell that selectively measures the residual oxygen, and which consequently is the primary measurement method, is used as the measuring technology for this analyser. This has the advantage that the user does not need to know which gas type is in the IG unit. On the display the gas concentration of the gas sample is shown. A rechargeable battery can be integrated as an option, which enables the devices to also be used directly on the construction site.

A sample is injected with a gas syringe. This offers the advantage that only minimal gas quantities are required and you can check the function of the gas analyser yourself.

Additional highlights of our analysers are high accuracy and long service life of the measuring cells – the service life is usually longer than 15 years! An additional advantage is the low quantity of consumables. Yearly factory calibration is not necessary!

For quality control in production we recommend use of the ISO-GAS-Control or GAS INSPECTOR analysers. These are more robust and in some cases have a greater function scope, extending to digital documentation of the measured values, including unique assignment of the analysed IG unit.

ISO-GAS-Control

For quality control in production we also recommend our analyser ISO-GAS-Control. For more than 25 years the ISO-GAS-Control has been used around the world for quality control of IG units.

Our proven analysis technology that is based on thermal conductivity is used as the measuring technology. HELANTEC has developed the associated sensor system specially for the insulated glass industry, including extensive signal processing and data evaluation. Only this combination enables the use of this measuring technology as a test method.

The ISO-GAS-Control is extremely robust and works for years with virtually no maintenance. It can be used universally for all standard gases and gas mixtures. The measured gas concentration is shown directly on the display.

The sample is injected via gas syringe. This offers the advantage that only minimal gas quantities are required and you can check the function of the gas analyser yourself.

Additional advantages of the ISO-GAS-Control are its high level of accuracy, and the long service life of the sensor system. Yearly factory calibration is not necessary!

A rechargeable battery can be integrated as an option, which enables the devices to also be used directly on the construction site.

The GAS INSPECTOR offers even more convenience and a greater function scope. This analyser is the test instrument for quality control for advanced insulating glass production.

GAS-TESTER

The GAS TESTER is our lowest-price entry-level model for monitoring gas concentration. Naturally we have installed our proven analysis technology in this product as well.

Features

- reliable concentration measurements

- compact and handy design

- easy operability

- argon and krypton use

- optional data storage

Only a small quantity of gas is required. Sampling is executed with a special gas supply pump. The argon gauge GAS TESTER is suitable for quality control of IG units with argon or krypton as the filling gas. If you desire to also analyse other gas types or gas mixtures, you should chose one of our other analysers.

We would be pleased to advise you in the selection of a suitable analyser for your requirements.

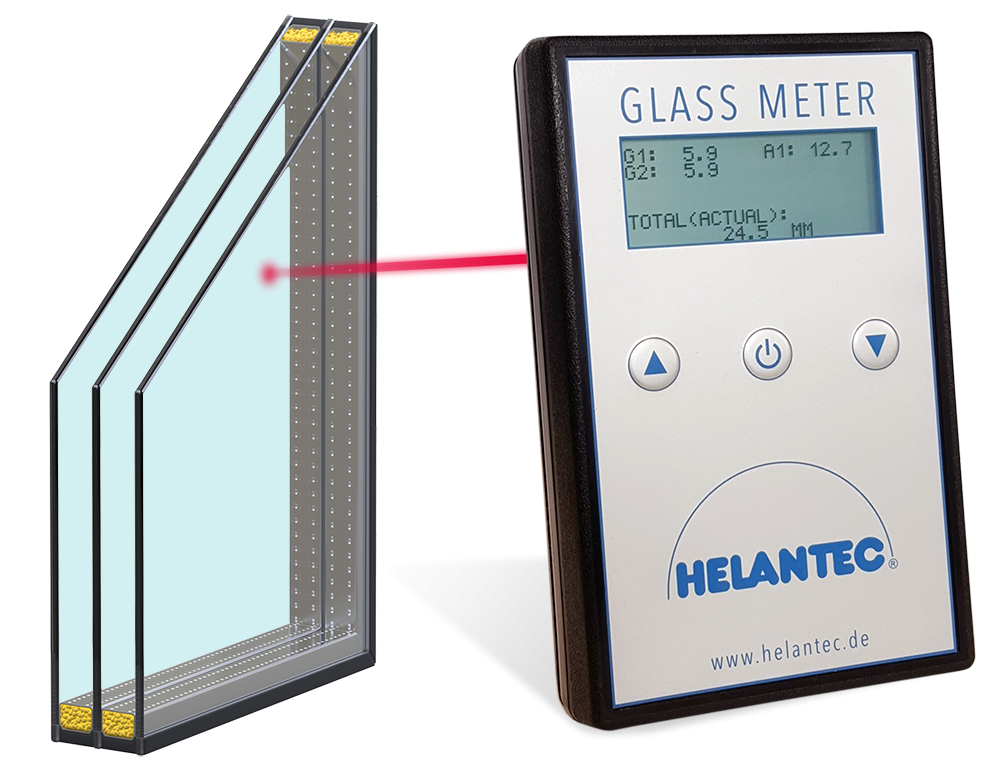

GLASS METER

For insulated glass production, reliable quality control is indispensable. Consequently, reliable test methods are even more important. With HELANTEC devices, you get the technology to check the quality of your products. All devices are easy to use and very accurate.

The GLASS METER is used for checking the thickness and distance of the glass panes, as well as the coatings.

Features

- reliable measurement (glass thickness / air distance / LOW-E coating)

- compact and handy design

- easy operability

- suitable for multi-coated IG units

- suitable for triple-glazed units and all spacer materials

- non-destructive measurement

We would be pleased to advise you in the selection of a suitable analyser for your requirements.

GAS INSPECTOR

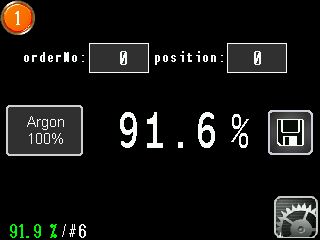

The gas meter GAS INSPECTOR represents a new generation of analysers for quality control.

Handwritten documentation of the quality control procedure is no longer contemporary. Quality assurance and verification of quality are of central significance, particularly with regard to the constantly increasing statutory construction regulations. These requirements can only be satisfied economically with digital data storage.

The GAS INSPECTOR enables digital documentation of the quality control process without additional effort. The measured gas concentration can be saved together with the barcode of the IG unit. Networking of production systems with a connection to the central database is already the state of technology for many companies. Now with the GAS INSPECTOR, HELANTEC also makes it possible to integrate the quality control in the existing network.

All data can be transferred into or called up from the company-internal quality management system via the integrated network interface.

Consequently tracing without any difficulty is possible. However, even without a network connection, the data can be downloaded or directly printed out in tabular form via a printer.

Our proven analysis technology that is based on thermal conductivity is used as the measuring technology. HELANTEC developed the associated sensor system specially for the insulated glass industry, including extensive signal processing and data evaluation. This measurement technology is extremely robust and works with virtually no maintenance.

The analyser can be used universally for all standard gases and gas mixtures. Yearly factory calibration is not necessary!

A sample is injected with a gas syringe. This offers the advantage that only minimal gas quantities are required and you can check the function of the gas analyser yourself at any time. This possibility is particularly important; simply “believing” measurement results was yesterday – today measurement results must be quickly and easily verifiable.